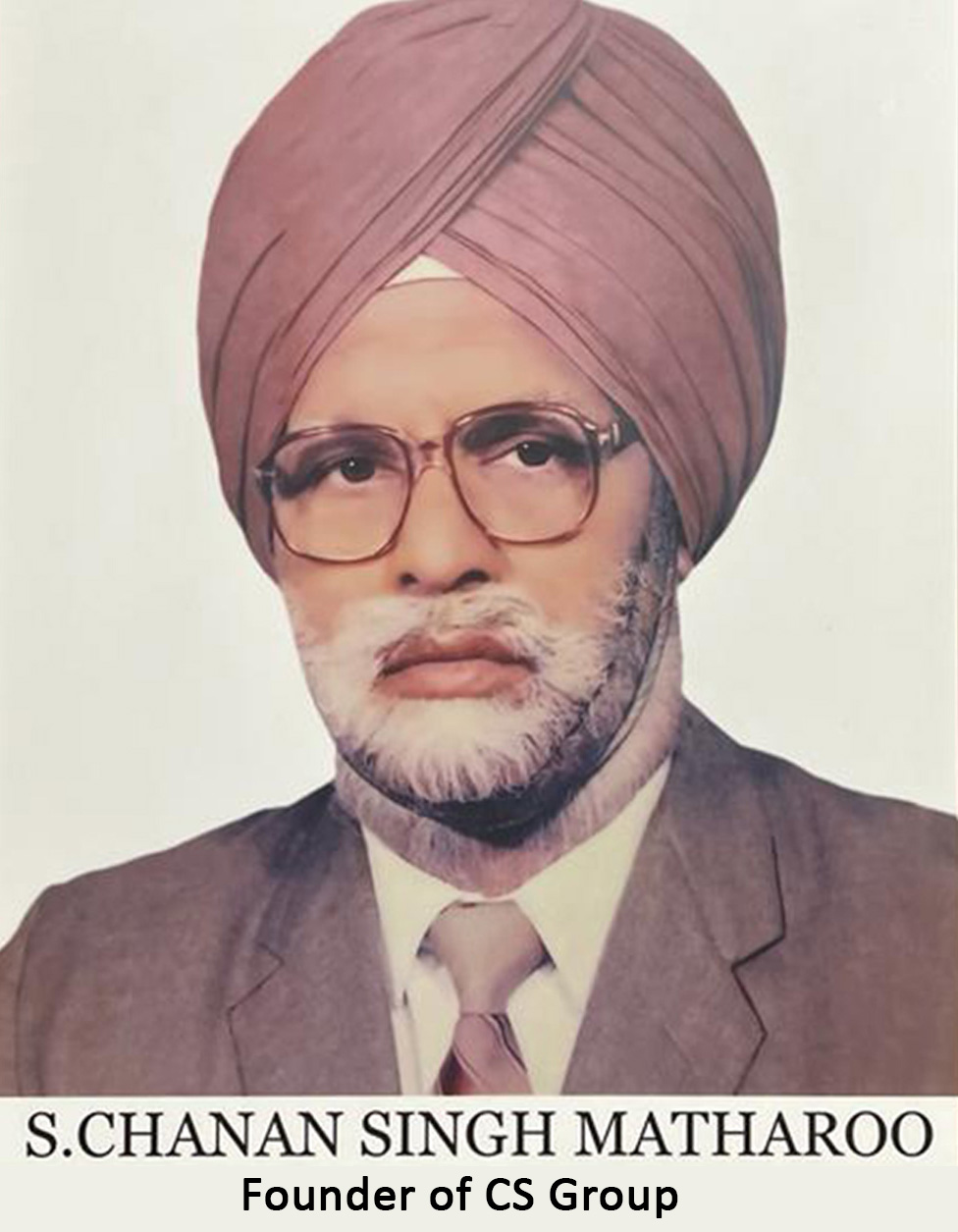

This organization came in existence in early 1995 basically born from its mother concern M/s Prince Steel Industries located at Mandi Gobindgarh “Steel Town” of Asia on National Highway between Amritsar and Delhi. founded by Sh. Chanan Singh Matharoo a self made industrialist who has rich experience in the field of manufacturing of Rolls.

Originally this organization was a very small but due to massive expansion revamping and modernization in the Re- Rolling Industry, the single unit was not able to meet high demand of Rolls then the management established forging plant with the name and style of M/s Amar Rolls with the induction of Art of Technology, for manufacturing Rolls.

Know More